Sanitation is a real issue for humanitarian professionals: wastewater evacuation and treatment, sludge management... The stakes are sanitary, environmental and epidemiological.

2 objectives

Health

Protect populations (beneficiaries and humanitarian personnel) by reducing faecal sludge-related diseases that can be transmitted through the environment and water resources.

Operational

Provide a low-carbon, local and sustainable sanitation solution for the humanitarian sector.

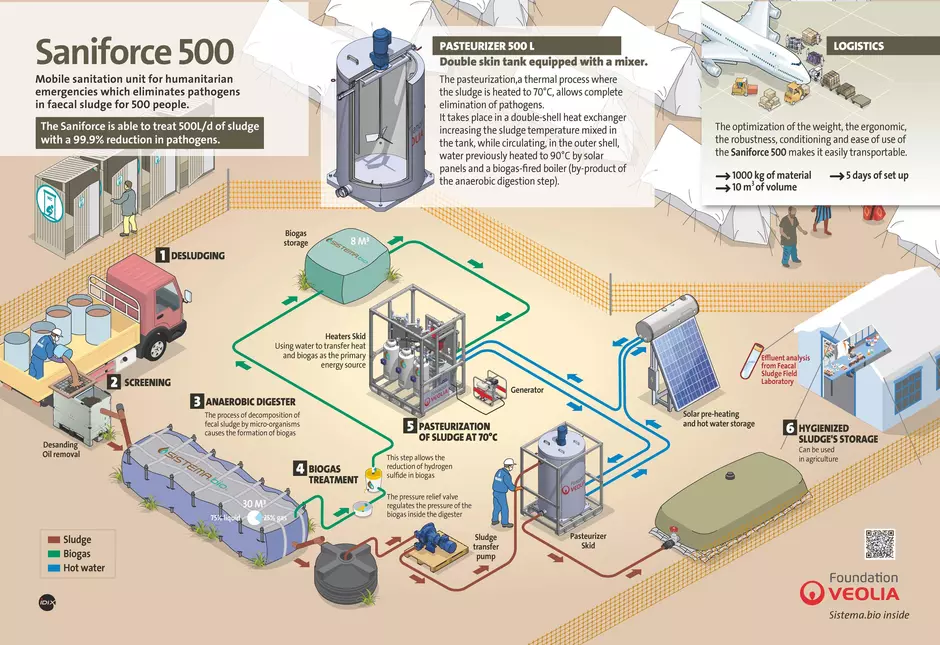

Technically, the system is based on the anaerobic digestion process. This controlled process of biological decomposition of the organic matter contained in the sludge takes place without oxygen and generates both biogas, which can be converted into energy, and a reusable effluent known as digestate. The reaction takes place in flexible biodigesters supplied by Sistema.bio.

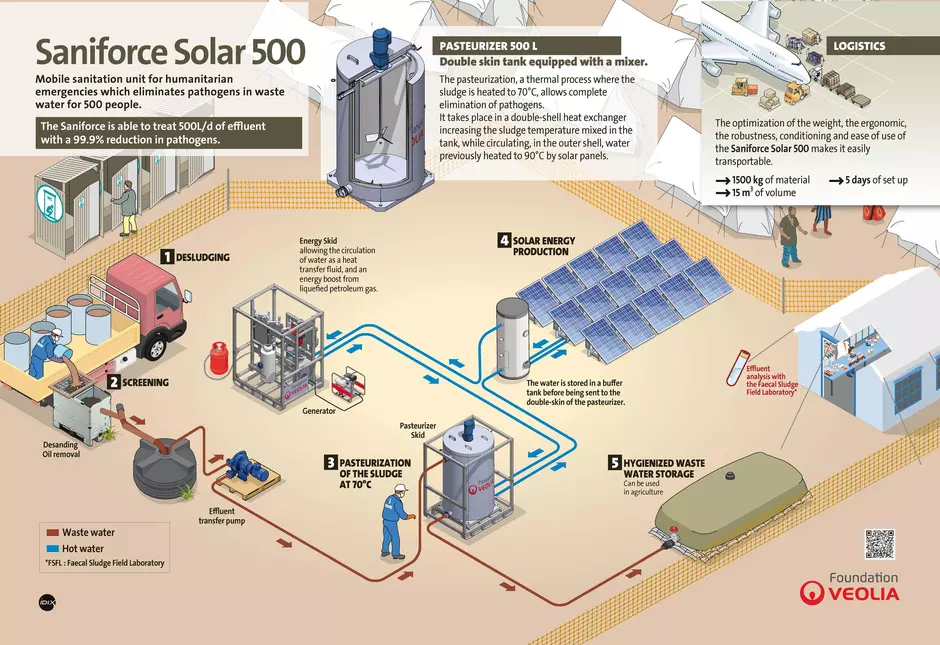

In the Saniforce set-up, the biogas is then valorized in a post-treatment phase, pasteurization, which consists of maintaining the digestate at 70° for one hour. At the end of the whole process, the material is 99.9% free of potential pathogens. This hygienized sludge, which can have a second life in agriculture, for example, takes on a new role in the wastewater treatment chain.

Fecal sludge is a real problem during humanitarian operations, usually in post-emergency situations. How can we protect populations from the pathologies carried by these flows? How can we ensure that what is returned to nature is not a vector for pollution? How can we protect the various resources needed to treat water and make it drinkable?

Humanitarian actors, who manage both access to essential services in emergency situations and, in the longer term, camps for displaced persons and refugees, are looking for solutions. The Veolia Foundation is familiar with the field and its constraints, having already developed mobile water purification stations (Aquaforces) designed for humanitarian situations. Since 2018, it has been working on sanitation solutions to meet the growing needs on the ground.

These systems, which serve the WASH (Water and Sanitation Hygiene) sector, provide humanitarian access to the essential services at the heart of the Veolia Group's expertise.

What are we talking about?

The Saniforce is a low-energy, sanitary fecal sludge treatment solution for humanitarian environments. It is designed to treat the contents of septic tanks and latrine pits for up to 500 people.

Find out about our partnership with the International Organization for Migration (IOM), a UN agency, to test the solar-powered version of Saniforce.

To test this system in real-life situations and adapt it to the needs of humanitarian aid workers, the Veolia Foundation is taking part in programs in Kenya, Uganda and Bangladesh.

Kenya, avec Opero, Sistema Bio | 2022

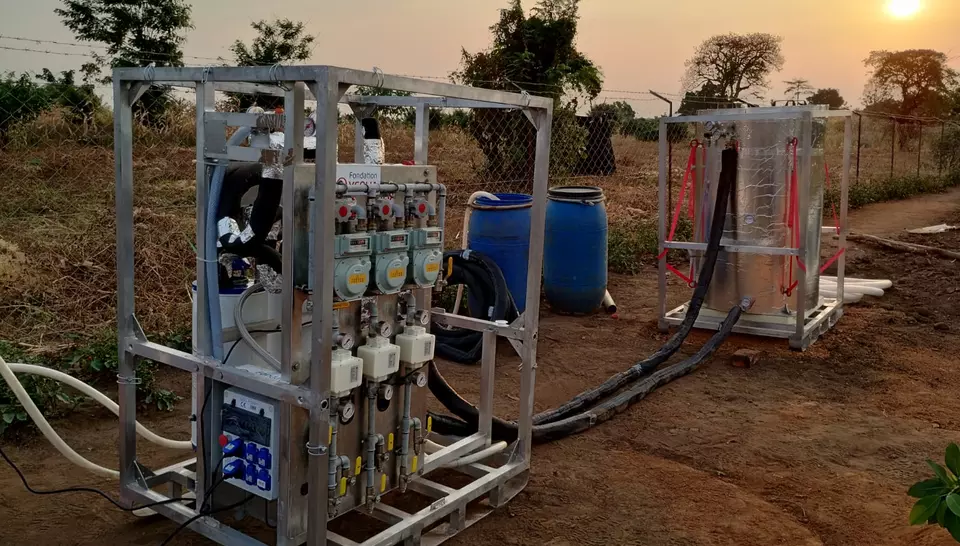

In Kisumu, western Kenya, Opero, a specialist in the development of water and sanitation services, is piloting a project to test Saniforce in 2022. The program brought together several experts in the field, including Mexican biodigester manufacturer SistemaBio and the Veolia Foundation. The tests carried out validated the pre-treatment and digestion process using human fecal sludge.

France, with the DEST research center, Veolia | 2023

In Limay, in the Ile-de-France region, Veoliaforce experts from the Group's various business lines took turns in autumn 2023 to test the Saniforce thermal model. For this post-treatment study, the Veoliaforce foundation relied on Veolia's Department of Scientific and Technical Expertise (DEST).

Uganda, with the World Food Program (UN), Opero and the Ugandan Red Cross | 2024-2025

In western Uganda, tens of thousands of people are fleeing the fighting between the M23 armed group and Congolese forces from the neighboring Democratic Republic of Congo. The Ugandan Red Cross, among other NGOs, is helping to set up refugee camps. Present in Kyangwali, it is one of the partners in a project supported by the World Food Program (WFP, a UN agency) to test the Saniforce in real-life situations.

The project has a number of aims: to put the Saniforce to the test in the field, to evaluate the overall process, in particular thermal sanitization, to document the whole process, and to look ahead to the potential reuse of effluent for agricultural purposes.

Deployment of the equipment, equipped with the FSFL laboratory for analysis and monitoring of sanitation systems, begins in April 2024 with four partners committed to the project's success:

Four partners committed to the UN World Food Program

- Objective: supply the technology for the pasteurization skid.

Leverage: skills sponsorship to manage the installation and commissioning of the skid; organize training sessions for the local team.

The timetable runs over several months, with Veoliaforce's expertise mobilised on several occasions to :

- Ensure start-up,

- Monitor operation and analysis,

- Consider areas for improvement.

From January to March 2025, three Veoliaforce experts were mobilized to deploy a Saniforce pilot in the Kyangwali refugee camp in Uganda. Romain Verchère, the Foundation's permanent staff member in charge of the innovation programme, and Paul Sagot, a Veolia Water research and technical project engineer, have joined Gabriel David, a student at the Polytechnic School of the University of Sao Paulo (Brazil), who is writing his dissertation on the Saniforce. Bruno Mathias, project manager at Veolia Water, then spent two weeks on site.

Bangladesh, with the International Office for Migration (UN) and Elrha | 2024-2025

In 2017, hundreds of thousands of Rohingya fled the violence in their villages in Myanmar and took refuge across the border in Cox's Bazar, Bangladesh. Seven years later, what has become one of the world's largest camps is home to over a million refugees. Among the players present, the International Office for Migration (IOM) is operating a fecal sludge treatment solution (DEWATS) with financial support from the NGO Elrha.

Faced with the persistence of pathogens such as cholera, this UN agency turned to Saniforce for its ability to rid the material of 99.9% of potential pathogens.

The IOM also wanted to focus on solar energy. While pasteurization (which consists in keeping the digestate at 70° for an hour) is carried out using biogas supplemented by solar energy in Uganda, the opposite is true in Bangladesh. Solar panels are used almost exclusively to power the system.

Both versions of Saniforce

To find out more

- The “FSFL” (Faecal Sludge Field Laboratory), a laboratory for the analysis and monitoring of sanitation systems designed by the Veolia Foundation for the humanitarian sector.

- Sanitation in refugee camps and our work in Myanmar

- Our work in Haiti with Médecins Sans Frontières to treat hospital effluent

- Veoliaforce skills sponsorship or the provision of Veolia expertise